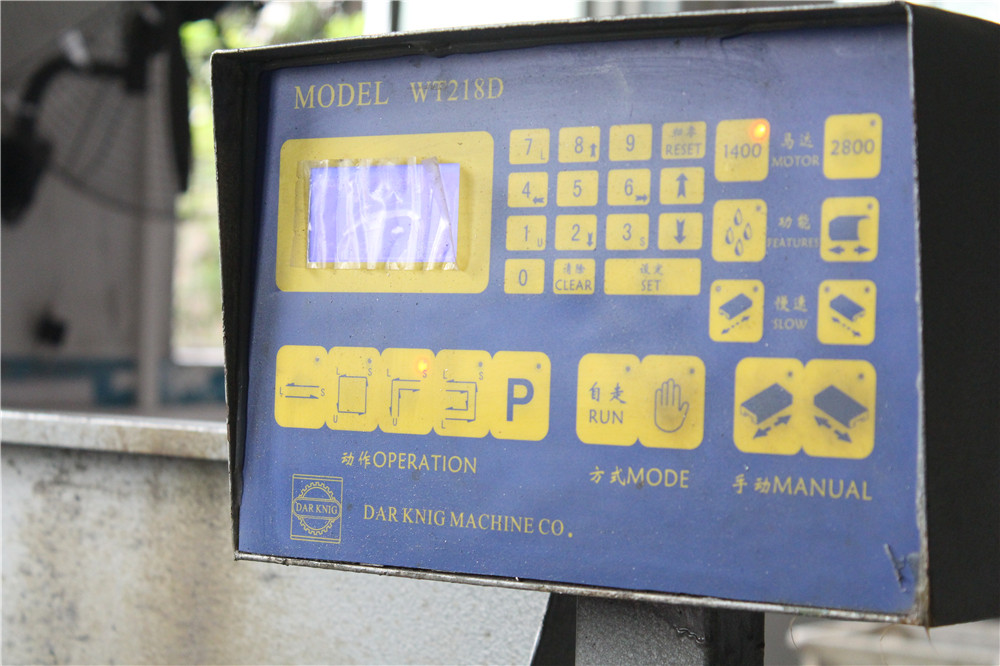

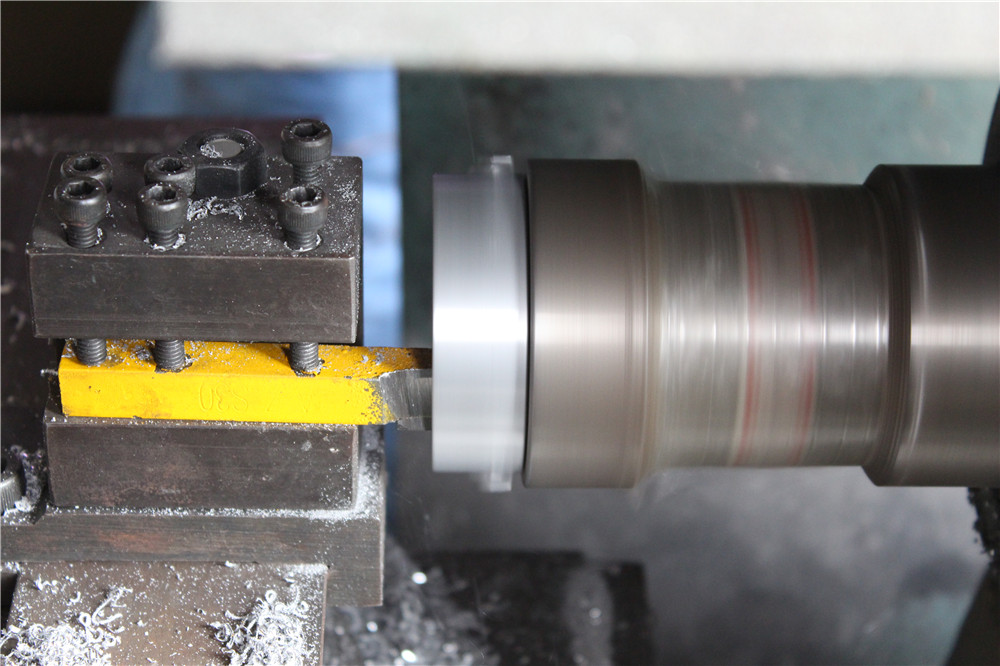

1. Machining

The downlight parts machining workshop uses 10 PLC lathes to machine components for ceiling lights. These components include the inner ring, outer ring and grooves. With an entire NCNC process, one person controls only two devices, thus saving costs. In addition, there are 10 drilling machines to drill holes in each part.

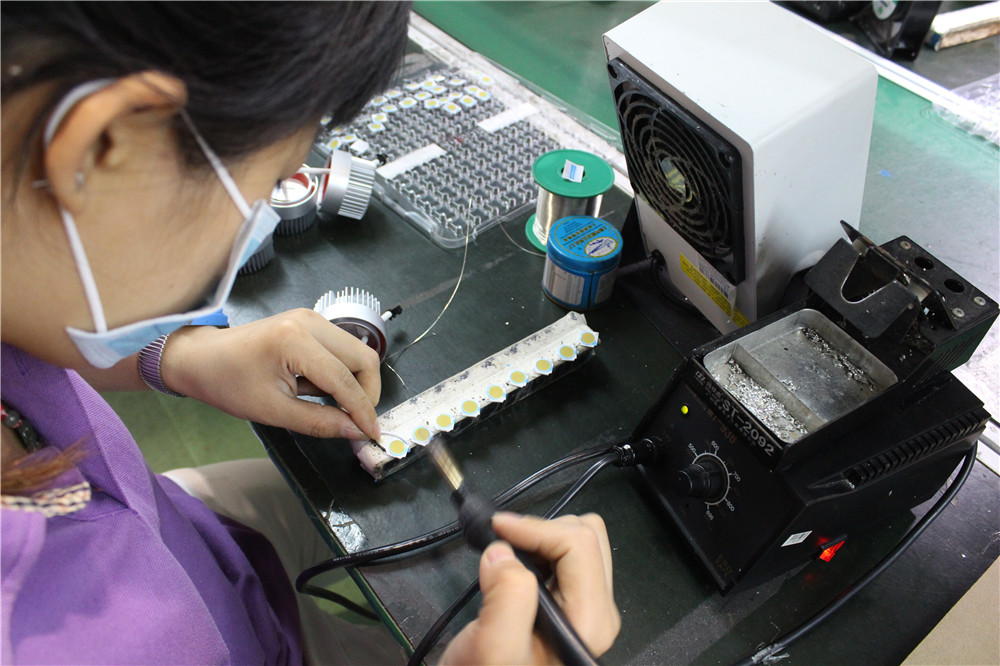

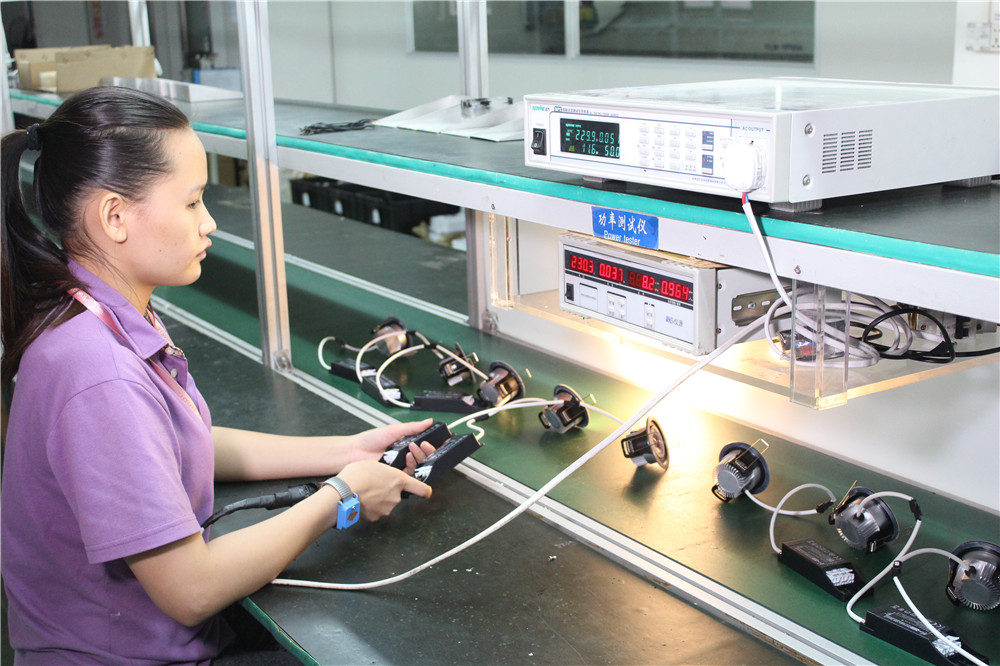

2. Assembly of LED Lights

2.1 The LED downlight assembly workshop has more than 20 workers, all of whom are well trained before employment and have at least 5 years of experience in assembly. The assembly line reaches a monthly output of 35,000 to 40,000 LED downlights. |LED DOWNLIGHT MANUFACTURER

2.2 Sticking fireproof material.

2.3 Weling the light source with lead-free process.

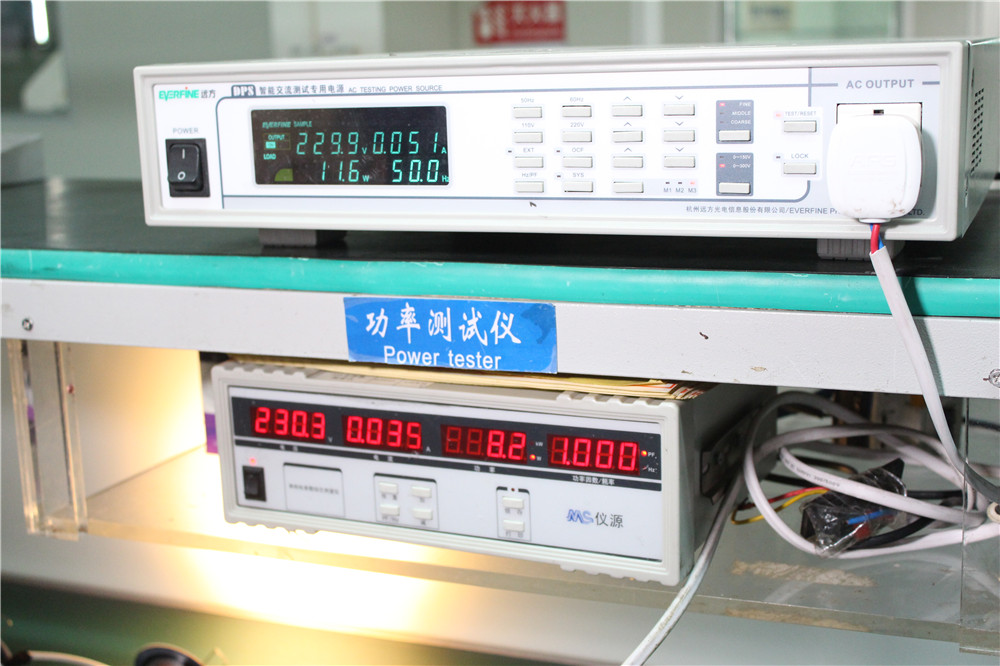

2.6 Connecting the LED downlight to the drive, and testing the power in order to ensure 100% ilumination.

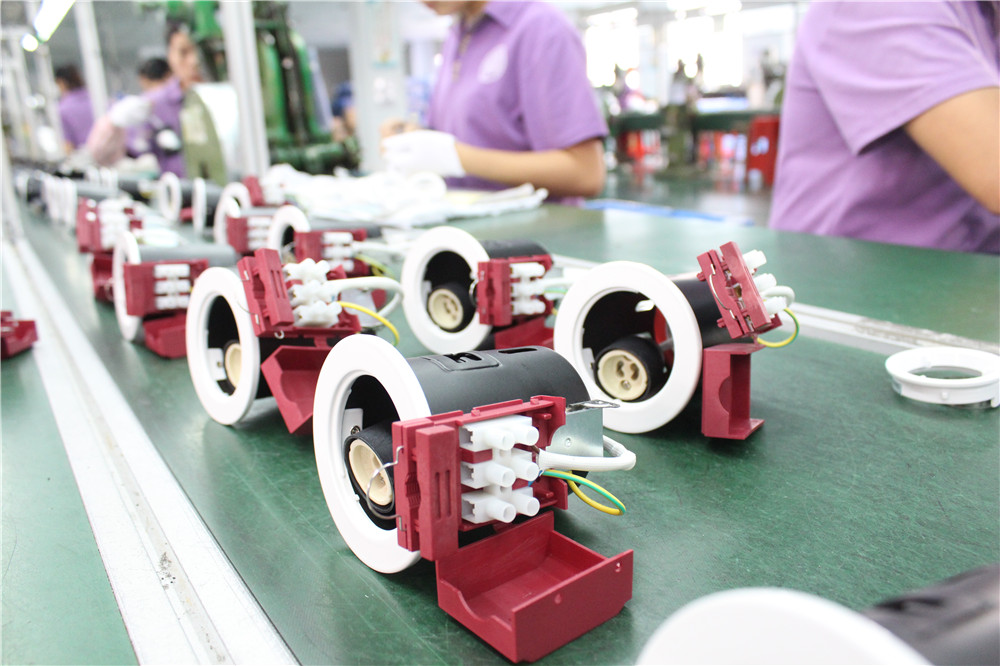

3. Assembly of Non-LED Downlights

3.1 The workshop for non-LED downlights covers an area of over 500 square meters and has more than 30 assembly

workers. The monthly production output here is about 200,000 pieces.

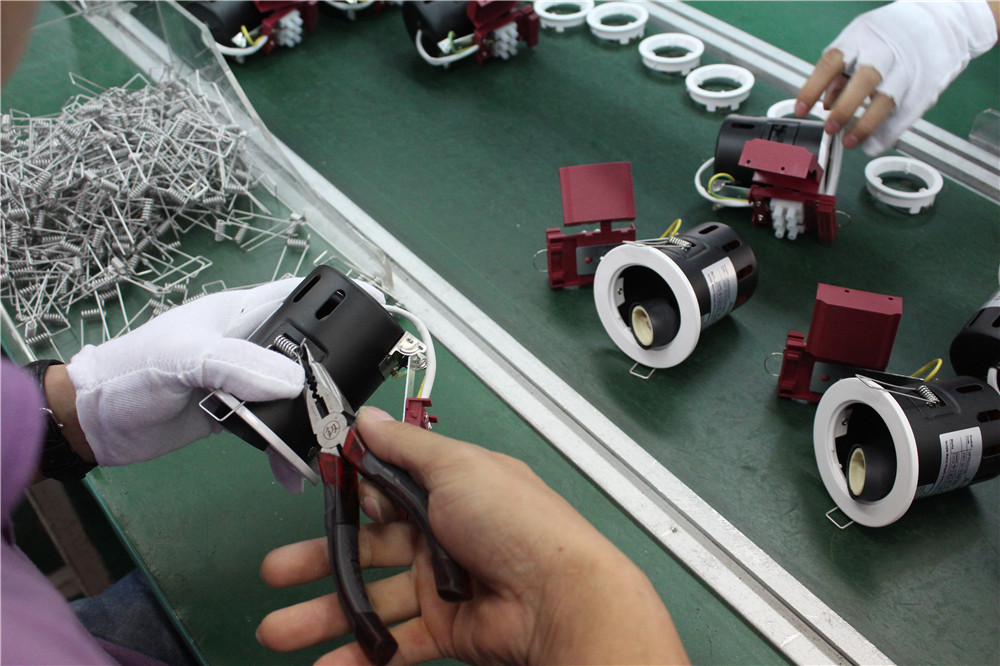

3.2 Fire rated cover rivets the stainless steel sheet, the holder and earth wire.

3.3 Installation of blinding posts and junction box.

3.4 Fix the screws of the internal wire pessing plate.

3.5 High-voltage test, tests according. to the testing standards of different types of lamps.

3.6 Intallation of spring

3.7 Testing the grounding resistor