1. Incoming Material Inspection

Here, employees are testing purchased parts. First, they inspect the surface condition for damage, scrapes, bubbles, holes, deformation, cracks, and color. We will only put parts into use that have passed inspection.

Shown here is ahesion esing for powder coating podut. Usig a knite to cut the 1mm thik sufae into smal chelcs, theadhesive tape is then atched. If the sutace of the tape fl from the product. the productis unqualified and will not be used.

The materials will packaged after inspection to avoid the damage. |high quality led downlights

2. Product Inspection

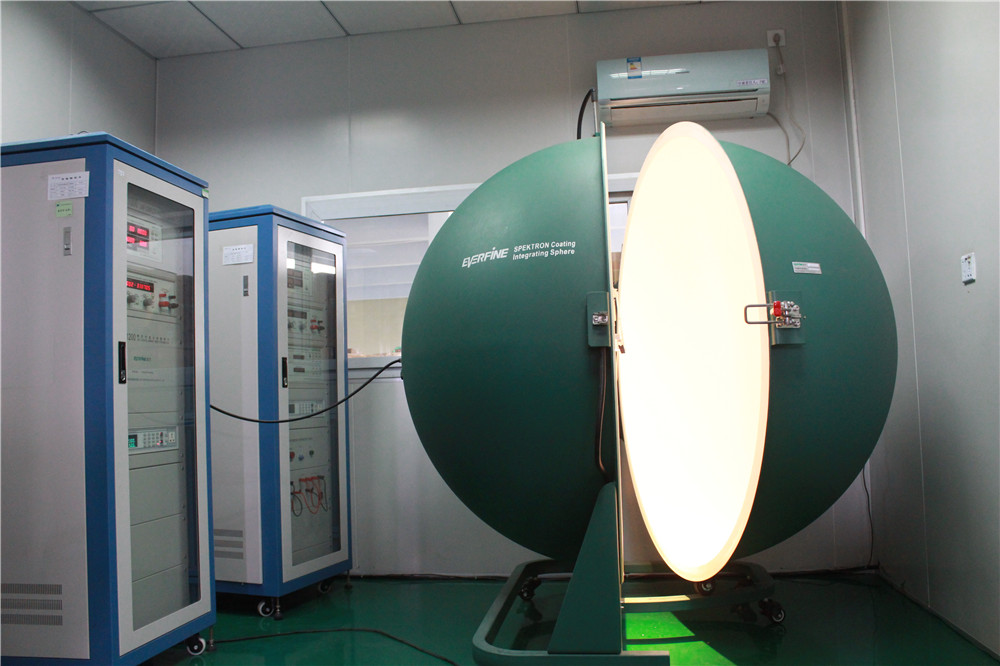

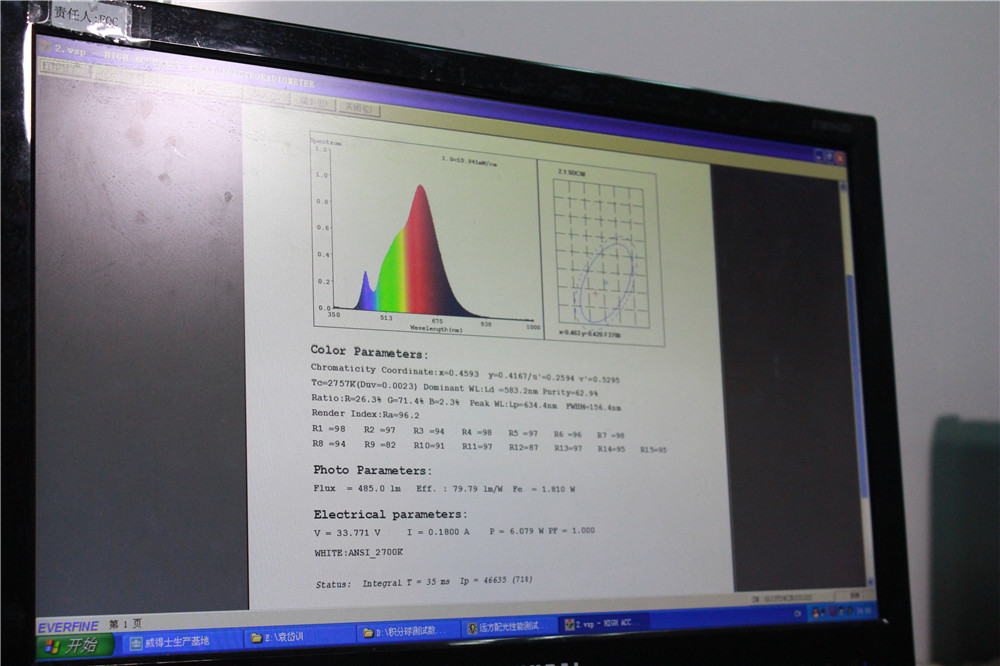

1) Optical and electrical test: Test the temperature, luminosity and electrical parameters

2) Waterproof test: Impact testing of the lighting product is executed by strong water flushing. The test time is about 15 minutes.

3) Salt spray test: our test time is about 24 to 72 hours. We will use only the materials that are not corroded and without air bubbles during the testing time.

4) Constant temperature test chamber: When the temperature rises to 45°C, the products are tested and observed for 24 hours.

5) In order to ensure the service life of the lights, we will choose samples from a batch to go through an aging test before delivery. The driver and the light source is tested one-to-one by the aging test. Our testing time is around 1470 minutes.

6) The finished product testing includes the outer box inspection, major structure test of the light, performance test (conduction test, voltage test, earth test) and LED power test (light spot, photoelectric parameters), labeling and instruction inspection, to ensure that the products have no failures before packaging.